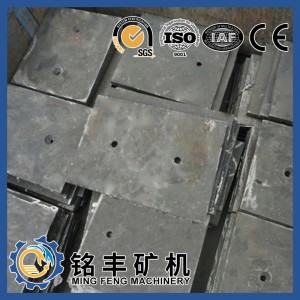

I-manganese yebhola yokusila ipleyiti ephezulu

Isishwankathelo:

| Uhlobo | Ibhodi ye-Crusher liner, i-lining plate | ||

| Imvelaphi | eTshayina | Ikhowudi ye-HS | 84749000 |

| Imeko | Entsha | Ukusila iintsimbi | I-Quartz, intsimbi yegolide, iklinka yesamente, njl. |

| Uhlobo lomatshini | Ball Mill Liner | Isiqinisekiso | ISO 9001:2008 |

| Izinto eziphambili | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Uhlobo Lokuqhuba | Iyaphosa | Unyango loMphezulu | Ukupholisha/Ukutshiza-Ipeyinti |

| Ukuphoswa kokuhlolwa | Isixhobo sokufunda ngokuthe ngqo se-Spectrum, uhlalutyo lwe-Metallographic, uHlolo lwe-Ultrasonic, uHlolo lweNcam yeMagnetic, uHlolo lweePropati zeMechanical | ||

| Ipakethe yezoThutho | Ipakishwe kwiPallet/Case | Isiqinisekiso | Iyafana neyoqobo |

| Umgangatho | Umgangato ophezulu | Amava | Ngaphezulu kweminyaka engama-30 |

Inkcazelo:

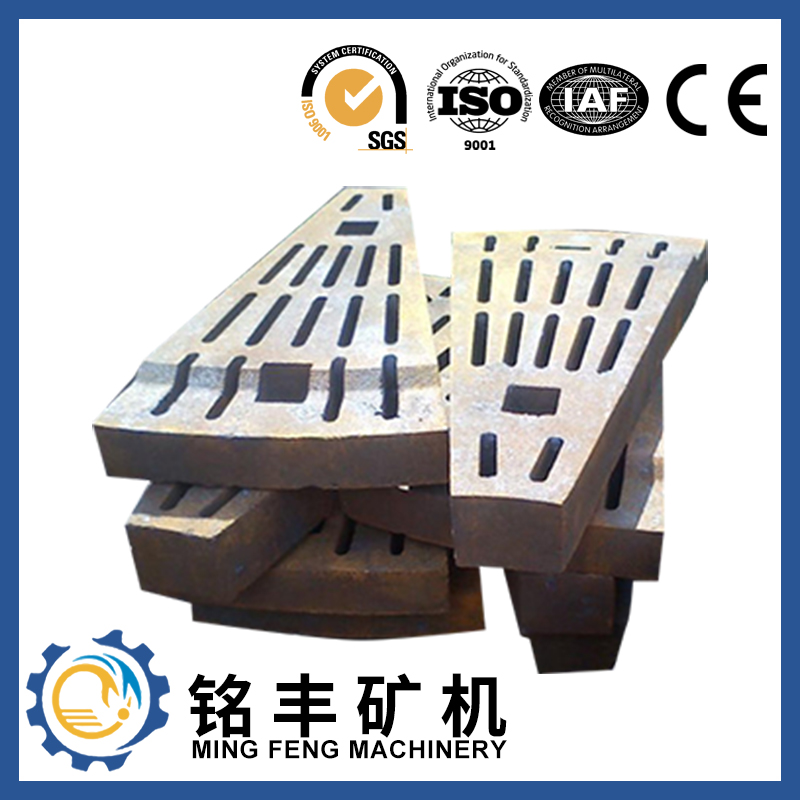

Okokuqala, i-liner sisiqwenga esiphuma ngaphakathi kwi-crusher.Ngenxa yokuba isixhobo sisixhobo esisetyenziswayo, oko kukuthi, xa sisebenza, iindawo zangaphakathi ziya kuguga ngokuthe ngcembe njengoko ixesha lokusebenza landa.Xa ukunxiba kufikelela kwinqanaba elithile Kwinqanaba elithile, izixhobo azikwazi ukusebenza kakuhle, kwaye umgca unokudlala indima yokukhusela ngaphakathi kwesixhobo, ukunciphisa ukunxiba okanye ukulimala kwezinye iindawo ngaphakathi kwi-crusher, enokunciphisa impembelelo ukusebenza kakuhle kwezixhobo.Nciphisa iindleko zokugcina iinxalenye.

Okwesibini, ibhodi ye-lining inokuphucula ukusebenza kakuhle kunye nemveliso ye-crusher, kuba ibhodi ye-lining ngokubanzi ibone amazinyo.Xa izixhobo zokutyumza izinto, amazinyo e-sawr angakwazi ukutyumza ngokufanelekileyo izinto, kwaye umphumo ubonakala kakhulu, kodwa esi siphumo siya kwenza amazinyo amazinyo kwaye Kukho ukungqubuzana phakathi kwezinto, okwenza ukuba amazinyo agqitywe ngokuthe ngcembe kwaye alahlekelwe yimpembelelo yawo.Ngoko ke, iiplati zetsimbi ezingcono zingasetyenziselwa ukucubungula i-liner ukuze kuphuculwe ukuqina kwayo kunye nokumelana nokugqoka.Oku kukwangcono kuphuculo lwamandla okusebenza kwezixhobo kunye nemveliso.Uncedo olukhulu.

Ulwakhiwo lweMchiza yeMathiriyeli yokuSasa:

| IManganess ePhakamileyo yokuCasa iMathiriyeli yeMichiza | |||||||

| Ikhowudi Elem. | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

Amalungu eCrusher:

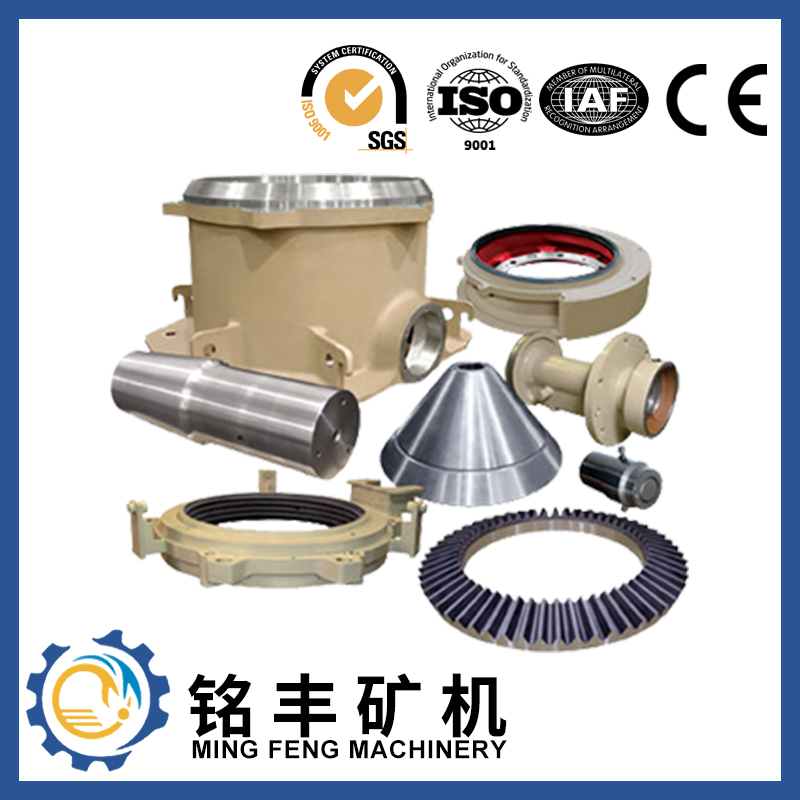

Sineendawo ezicwangcisiweyo zokutshiza ezichanekileyo ezibandakanya intloko, izitya, i-shaft engundoqo, i-socket liner, i-socket, i-eccentric bushing, i-head bushings, i-gear, i-countershaft, i-countershaft bushing, i-countershaft house, i-liner yesihlalo esikhulu kunye nokunye, sinokuxhasa umatshini wakho wonke. iindawo ezisecaleni koomatshini.

Kutheni ukhetha thina?

Iminyaka eyi-1.30 yamava okuvelisa, iminyaka emi-6 yamava orhwebo lwangaphandle

2.Ulawulo olungqongqo lomgangatho, ilebhu eyeyayo

3.ISO9001:2008, BUREAU VERITAS

IMVELISO YOKUTHENGISA OKUSHISAYO

Umgangatho Wokuqala, Ukhuseleko luqinisekisiwe